PUT FLEX IN YOUR BOOM!

Boom Mat’s regular aluminium damping material has long been used to reduce vibration and noise while providing insulation to protect against extreme heat and cold.

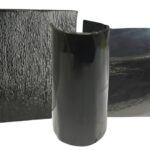

Now, meet Boom Mat Flex, a material that is pliable enough to be used anywhere in a vehicle, even in the most challenging areas such as those with tight curves. Unlike Boom Mat Aluminium, Boom Mat Flex easily conforms to odd shapes and tighter bends making it ideal to use inside wheel wells, mudguards or around tubing and pipes.

This new flexible peel and stick damping material are available in packs of two, four or ten.

Each section measures 12in x 12in square and can be trimmed to the exact size required.

Boom Mat Flex is made from 2.5mm thick Butyl rubber and has a clear poly surface with a black textured finish.

The product’s aggressive adhesive backing allows it to be shaped and secured firmly around any surface to reduce bothersome noise while adding heat insulation. It is also a great way to protect the paint on new, custom, or luxury vehicles.

Boom Mat Flex also has the potential to be used for many purposes other than automotive. For the home, it can be used to sound-proof a home theatre, music room or workshop, or for reducing noise from sheet metal heating and cooling ducts; for commercial and industrial applications it can be used wherever sound-damping is needed.

For more information about Boom Mat Flex (part #050225, 050227, 050228) and other innovative heat and sound solutions visit: www.DesignEngineering.com or their UK distributor, www.nimbusmotorsport.com ENDS.

| Print article | This entry was posted by admin on May 4, 2018 at 9:40 am, and is filed under News. Follow any responses to this post through RSS 2.0. Both comments and pings are currently closed. |

Comments are closed.